Product details

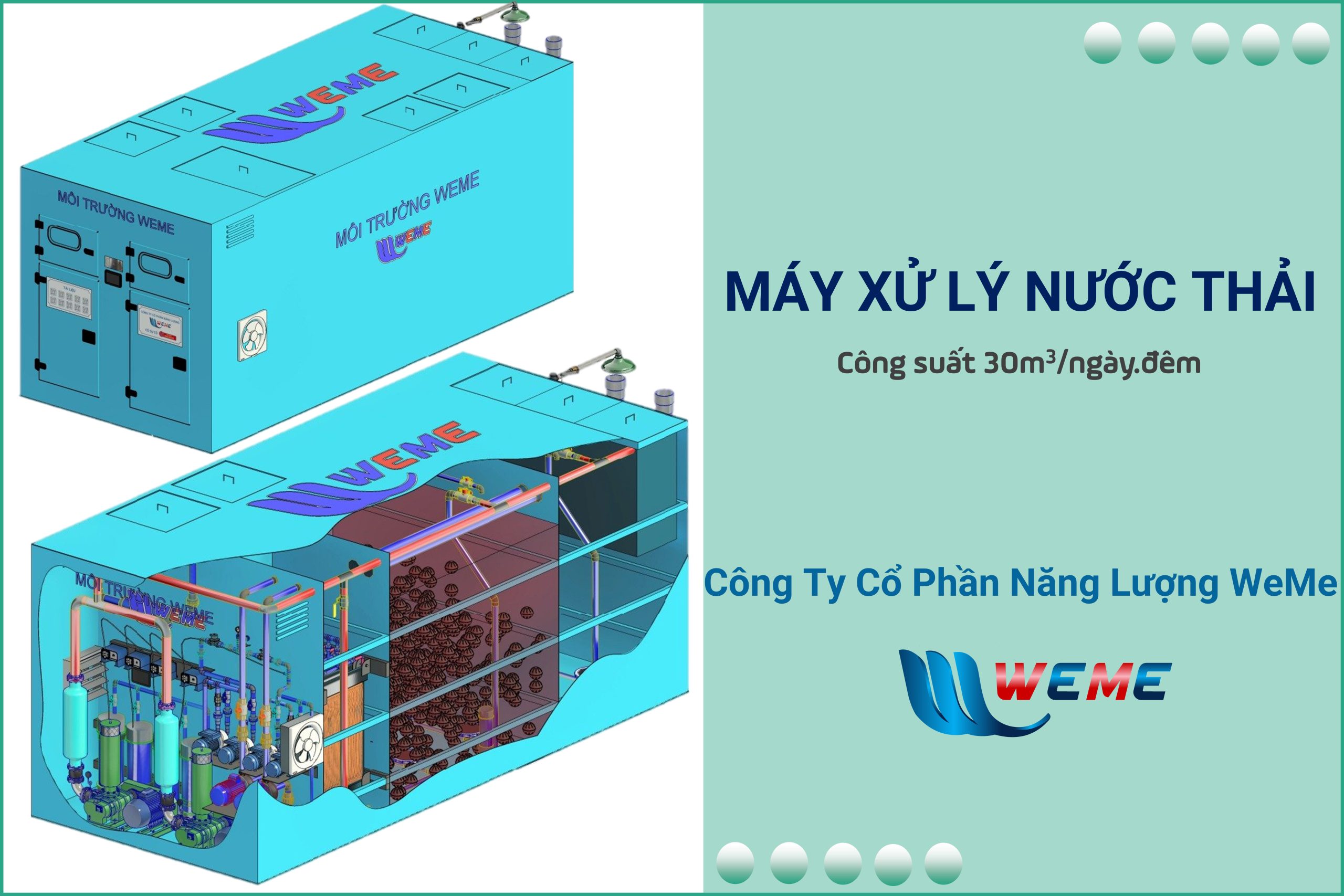

Wastewater treatment plant with capacity of 30m3/day.night

Learn more about the 30m3/day wastewater treatment machine of WeMe Energy Joint Stock Company, including its structure, design, and the types of wastewater it can treat!

Technical Specifications

- Product Name: Wastewater Treatment Machine

- Capacity: 30m3/day

- Power Supply: 3-phase – 380V

- Dimensions: Length x Width x Height = 5,350 x 2,300 x 2,300 mm

- Technology used: Biological combined with MBR membrane filtration

- Design and Construction Unit: WeMe Energy Joint Stock Company

- Illustration of the 30m3 wastewater treatment machine

Wastewater treatment machine with a capacity of 30m3/day

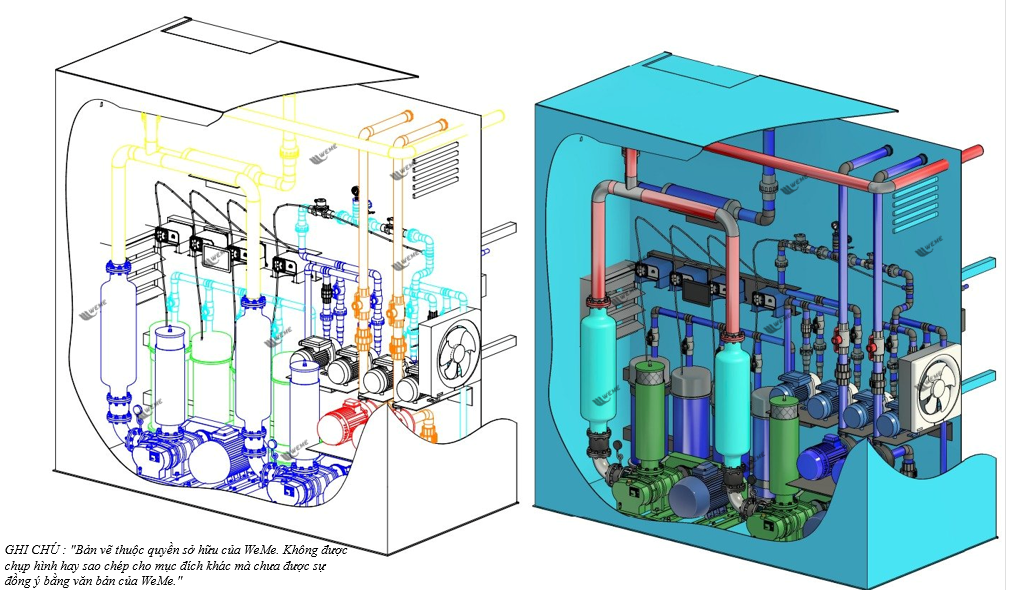

Structure

The machine consists of four main components as follows:

- Anoxic Tank: For projects with oil and grease, a grease separator is designed to separate the grease layer.

- Aeration Tank: This tank contains carriers to increase the contact area between microorganisms and wastewater.

- MBR Membrane Tank: The MBR membrane is placed here, and microorganisms, pollutants, and sludge are completely retained, allowing only clean water to pass through the membrane.

- Equipment and Control Room: All equipment used to control the wastewater treatment machine is placed here, saving space for building a control house and enhancing aesthetics.

Operation Mechanism

Technology Diagram

Technology Explanation

Collection Tank

Domestic wastewater, after being separated from grease and solid waste, and wastewater from the septic tank, is collected in the collection tank. A submersible pump is placed in this tank to pump wastewater to the balancing tank, initiating the treatment process.

Balancing Tank

This tank balances flow and concentration. Air is supplied to stir the wastewater, preventing anaerobic decomposition that could cause odor. From the balancing tank, a submersible pump transfers the wastewater to the anoxic tank.

Anoxic Tank

The anoxic tank handles anaerobic treatment. Air is supplied to enhance the flocculation activity of microorganisms, increasing the activity of sludge flocs while inhibiting the growth of filamentous microorganisms that cause sludge bulking and foaming. In this tank, processes like carbon removal, nitrate denitrification, and phosphorus removal take place.

Aeration Tank

Next, the wastewater flows automatically into the aeration tank for aerobic treatment. Oxygen is provided through an air blower operating 24/7, ensuring even air distribution for microbial reactions. Microorganisms break down organic substances into CO2 and H2O, reducing contamination levels. A submersible pump is used to pump wastewater to the MBR tank.

MBR Tank – WeMe

In the WeMe MBR tank, microorganisms are introduced to remove BOD, COD, nitrogen, phosphorus, and other contaminants. The microorganisms consume the organic matter in the wastewater and utilize it as a nutrient source. Subsequently, the wastewater is pumped through the MBR membrane, where microorganisms, pollutants, and sludge are retained, allowing only clean water to pass through the membrane.

The treated water meets discharge standards according to QCVN 14:2008/BTNMT. The treated water is discharged into the environment or into the area’s common sewage system.

Outstanding Efficiency of the 30m3 Wastewater Treatment Machine

During operation, the 30m3 wastewater treatment machine consistently meets the following criteria:

- MBR treatment efficiency for COD and BOD reaches about 90-95%.

- Easy to upgrade capacity by up to 20% without increasing tank volume.

- Increases biological treatment efficiency by 10-30% due to MLSS being 2-3 times higher than in traditional aeration tanks.

- The output water quality meets the required standards.

Advantages of the Domestic Wastewater Treatment Machine

- Saves construction space by replacing multiple units: Sedimentation Tank, Intermediate Tank, Filtration Tank, and Disinfection Tank.

- Aesthetic design

- Easy and quick transportation

- Installation within 30 days

- Cost-effective investment for business needs

- Easy to operate and saves on operational costs

- The treated water can be reused for irrigation, road cleaning, etc.

The machine can treat various types of wastewater such as:

- Wastewater from factories with 3,000-5,000 workers

- School wastewater

- Hospital wastewater

- Wastewater from resettlement areas

- Wastewater from business service areas

- Airport wastewater

- Fishing port wastewater

WeMe’s Domestic Wastewater Treatment Service

WeMe’s wastewater treatment machines stand out for their stable operation, minimal maintenance requirements, energy efficiency, reduced long-term operating costs, and selection of the most advanced technology. The machine’s smart design saves installation space and can easily be integrated into existing wastewater treatment systems. Additionally, WeMe ensures strict compliance with environmental regulations, making our products a sustainable choice that contributes to environmental protection.

Choosing WeMe’s wastewater treatment machine is not only a technical solution but also a commitment to the community and the environment.

WeMe Energy Joint Stock Company

| Headquarters | : 124/1 Ly Thuong Kiet, Ward 7, Go Vap District, Ho Chi Minh City |

| Hotline | : 0906.653.007 |

| : wemecompany@gmail.com | |

| Fanpage | : Môi Trường WeMe |

| Northern Region (Consultant) | : 0845.653.007 |

| Central Region (Consultant) | : 0847.653.007 |

| Southern Region (Consultant) | : 0824.653.007 |