Food wastewater treatment

Food wastewater treatment

- Overview of food processing wastewater

- Common concerns of food processing facility owners regarding their production wastewater

- Proposed solutions for food processing wastewater treatment

- Introduction to WeMe’s food processing wastewater treatment system

- Introduction to some food processing wastewater treatment projects by WeMe

- WeMe – A company with many years of experience in the environmental field

According to the General Statistics Office, in recent years, the food processing industry has experienced remarkable growth. This is one of the key industrial sectors with great development potential. Alongside this growth, the industry is exerting considerable pressure on the environment, including the issue of food processing wastewater treatment.

Overview of food processing wastewater

This industry is characterized by high water consumption, leading to a significant amount of wastewater generated. Below are some food processing sectors that generate wastewater that must be collected and treated:

- Processing and preserving meat and meat products;

- Processing and canning seafood, frozen seafood;

- Fish sauce production;

- Noodle production;

- Processing and preserving fruits and vegetables;

- Production of cakes and candies;

- Production of prepared foods;

- Production of animal, poultry, and aquatic feed;

- Dairy processing and dairy product manufacturing;

- …

Depending on the type and scale of production, the characteristics of the wastewater will vary. However, in general, food processing wastewater contains:

- Organic substances of plant and animal origin (COD, BOD, N, P, etc.);

- Suspended solids;

- Fats, oils, and greases from both animal and plant sources;

- Detergents used in machine cleaning and employee activities;

- Pathogenic microorganisms;

- …

To contribute to reducing environmental pollution issues, in addition to proactively building businesses based on sustainable development models, the government has established regulations regarding discharge for food processing facilities. Therefore, it is essential to design and install a suitable food processing wastewater treatment system.

Common concerns of food processing facility owners regarding their production wastewater

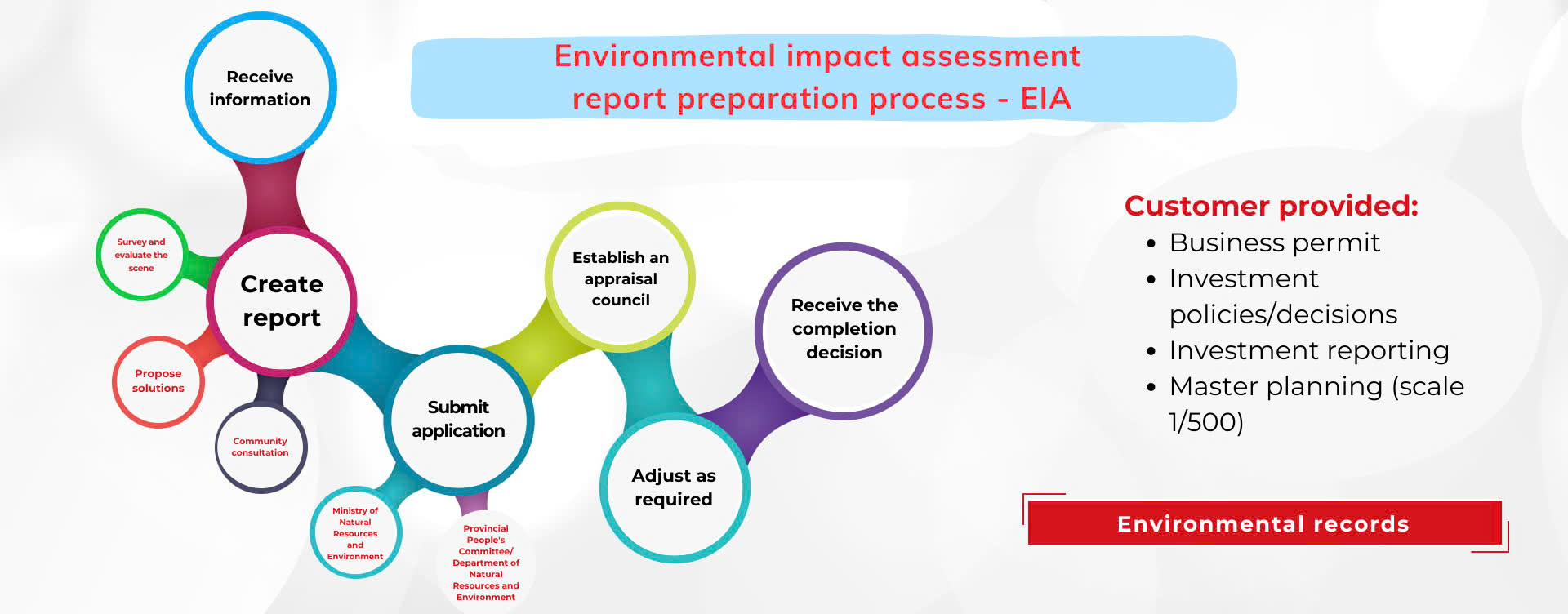

In addition to legal documentation, environmental records are also a concern for facility owners. One of these concerns is that the facility’s wastewater discharge must meet legal standards. According to Decree 155/2016/ND-CP, failure to treat wastewater and direct discharge into the environment can result in administrative fines ranging from 30,000,000 to 50,000,000 VND, and even revocation of the facility’s operating license. Factors that facility owners need to consider when building a food wastewater treatment system include:

- What is the type and scale of the production facility?

- What wastewater treatment technology is suitable for that type of production?

- What are the treatment efficiency, initial investment cost, and land area requirements?

- Will the treated wastewater meet the required standards?

Proposed solutions for food processing wastewater treatment

Table 1: Introduction to wastewater treatment technologies

| Technology | Advantages | Disadvantages |

|---|---|---|

| Traditional physico-chemical – biological method (Aerotank) | Capable of treating wastewater with high organic BOD loads | Must always maintain suitable conditions for microorganism growth |

| Effectively treats suspended solids, surfactants, and oils | Low efficiency in treating N and P nutrients | |

| Produces a large amount of sludge | ||

| Anaerobic biological treatment – UASB | Effectively treats nutrient pollutants N, P | Long time required for microorganism cultivation |

| Produces little sludge | Complex microorganism cultivation conditions (sealed tank, water pumped from below) | |

| Batch biological treatment – SBR | Effectively treats wastewater with high CHC and nitrogen content | System control and maintenance is quite difficult |

| Requires less energy for operation | Overflow wastewater may carry along sludge |

Each treatment technology has its own advantages and disadvantages. Depending on the investor’s needs, the appropriate technology should be selected. With many years of experience in the environmental field, WeMe proposes combining biological treatment with MBR membrane filtration technology for food processing wastewater treatment. Why do we recommend this technology for our customers?

Introduction to WeMe’s food processing wastewater treatment system

WeMe’s food processing wastewater treatment system applies aerobic treatment technology combined with modern MBR membrane filtration. The system has been thoroughly researched by top experts to ensure the best quality and output wastewater treatment efficiency.

Technical specifications

- Product name: Food processing wastewater treatment system

- Capacity: 5 m³/day to 40 m³/day

- Power supply: 3-phase, 380V

- MBR membrane tank size: 650 x 2,000 x 2000 mm

- Technology: Biological treatment combined with MBR membrane filtration

- Structure: Integrated, monolithic

- Design and construction unit: WeMe Energy Joint Stock Company

Table 2: List of equipment for food processing wastewater treatment system

| No. | Equipment Name | Quantity | Unit | Origin |

|---|---|---|---|---|

| 1 | MBR membrane tank | 1 | Set | WeMe Environment |

| 2 | MBR membrane | 2-12 | Membrane | Mitsubishi – China |

| 3 | MBR membrane fixing details | 1 | Set | WeMe Environment |

| 4 | Air blower | 1 | Set | Shenghong – Taiwan |

| 5 | Air distribution system | 1 | System | Vietnam |

| 6 | Electric valve | 2 | Set | UniD – Taiwan |

| 7 | Water meter | 2 | Set | Phu Thinh – Vietnam |

| 8 | Horizontal pump | 2 | Set | Panasonic – Indonesia |

| 9 | Electrical cabinet | 1 | Set | WeMe Environment |

| 10 | Dosing pump | 1 | Set | Hanna – Romania |

| 11 | Submersible wastewater pump | 1 | Set | Evak – Taiwan |

Pricing for food processing wastewater treatment systems with capacities of 5 – 40 m³

Table 3: Pricing for food processing wastewater treatment systems from WeMe

| No. | Capacity | Price (VND) | Note |

|---|---|---|---|

| 1 | 5 m³/day | 227,200,000 | Cost includes VAT (8%) and full package:

|

| 2 | 10 m³/day | 261,700,000 | |

| 3 | 15 m³/day | 313,900,000 | |

| 4 | 20 m³/day | 345,400,000 | |

| 5 | 25 m³/day | 484,200,000 | |

| 6 | 30 m³/day | 532,200,000 | |

| 7 | 35 m³/day | 554,200,000 | |

| 8 | 40 m³/day | 608,200,000 |

Outstanding advantages of MBR membrane technology

This system treats food processing wastewater using biological treatment combined with MBR membrane filtration. Wastewater passing through the MBR membrane does not require settling, filtration, or disinfection tanks as in other technologies, saving investment costs and installation space for investors.

Operating mechanism of the system is as follows:

- Wastewater, after separating trash and grease, is collected in the sump. A submersible pump is installed in the sump to pump wastewater to the equalization tank, beginning the treatment process.

- Equalization tank: Balances the flow and concentration of the wastewater. Air is supplied to mix the wastewater, preventing anaerobic decomposition and foul odors. Wastewater from the equalization tank is pumped through a submersible pump to the anaerobic treatment tank.

- Anaerobic tank: Wastewater is sent to the anaerobic tank, where dissolved organic matter and colloids are decomposed by anaerobic microorganisms to reduce COD and BOD in the wastewater. Anaerobic microorganisms use the dissolved organic matter and break it down into gases such as CO2, H2S, and CH4.

- Aerobic tank: Oxygen is supplied continuously by alternating air blowers to ensure even air distribution, allowing aerobic microorganisms to break down organic matter into CO2 and H2O, reducing the concentration of pollutants in the wastewater.

- MBR Module: Provides a supply of microorganisms necessary for the removal of BOD, COD, N, and P from the water. These microorganisms use the organic matter in the wastewater as a nutrient source, breaking it down into simpler compounds. The wastewater is then pumped through the MBR membrane, where microorganisms, pollutants, and sludge are completely retained on the membrane surface. Only clean water is allowed to pass through. The treated wastewater meets QCVN 40:2011/BTNMT column A/B standards for discharge into receiving sources.

Introduction to some food processing wastewater treatment projects by WeMe

Installation of wastewater treatment system for Dao Duy Phuong noodle production facility

- Capacity: 5 m³/day

- Wastewater type: Noodle production wastewater

- Required output water quality: QCVN 14:2008/BTNMT Column B (based on 5 main indicators: pH, BOD, TSS, Total Nitrogen, Coliform)

- Project location: Group 4, Lien Thanh Hamlet, Vinh Phuong Commune, Nha Trang City

- Investor: Mr. Dao Duy Phuong’s noodle production facility

Installation of wastewater treatment system for Duong Bang Food Company

- Capacity: 50 m³/day

- Wastewater type: Noodle production wastewater

- Required output water quality: QCVN 40:2011/BTNMT Column B (based on 7 main indicators: pH, BOD, COD, total phosphorus, suspended solids, total nitrogen, Coliform)

- Project location: Lot 8, Road 11, Tan Duc Industrial Park, Huu Thanh Commune, Duc Hoa District, Long An Province

- Investor: Duong Bang Food One Member Limited Company

Installation of wastewater treatment system for Nhu fresh pork skin production facility

- Capacity: 5 m³/day

- Wastewater type: Pork skin production wastewater

- Required output water quality: QCVN 40:2011/BTNMT Column B (including 11 specific indicators: temperature, color, pH, BOD5 (20oC), COD, suspended solids, total mineral oil, ammonia (calculated as N), total nitrogen, total phosphorus (calculated as P), Coliform)

- Project location: No. 95B, Tan Quoi Dong Hamlet, Truong An Ward, Vinh Long City

- Investor: Nhu fresh pork skin production facility

WeMe – A company with many years of experience in the environmental field

WeMe Energy Joint Stock Company is confident with many years of experience in the environmental field, especially in food processing wastewater treatment. We ensure our reputation by providing customers with wastewater treatment systems or modules with flexible capacities tailored to the production scale of the facility.

If you are interested in WeMe’s services, feel free to send us a message or leave your contact information HERE. WeMe will contact you as soon as possible to provide consultation and answer all your questions. Accompanying our customers is WeMe’s pride and honor.

WeMe Energy Joint Stock Company

| Headquarters | : 124/1 Ly Thuong Kiet, Ward 7, Go Vap District, Ho Chi Minh City |

| Hotline | : 0906.653.007 |

| : wemecompany@gmail.com | |

| Fanpage | : Môi Trường WeMe |

| Northern Region (Consultant) | : 0845.653.007 |

| Central Region (Consultant) | : 0847.653.007 |

| Southern Region (Consultant) | : 0824.653.007 |