Aquatic wastewater treatment

Aquatic wastewater treatment

- Why is it necessary to treat seafood wastewater?

- WeMe’s MBR Technology Solution for Seafood Wastewater Treatment

- WeMe’s Seafood Wastewater Treatment System Quotation

- WeMe’s Project Implementation Process

- Introduction to some similar wastewater treatment projects by WeMe

- Which can WeMe’s seafood wastewater treatment system be applied to?

With the advantage of bordering the East Sea and a coastline of 3,260 km, favorable for fishing and aquaculture, fisheries are considered one of Vietnam’s key economic sectors. Along with development opportunities, there are also environmental challenges. Wastewater from the seafood industry contains large amounts of pollutants harmful to the environment and human health. Therefore, investing in seafood wastewater treatment processes before discharge is a mandatory requirement for factories, businesses, and aquaculture facilities.

Why is it necessary to treat seafood wastewater?

Origin and composition of seafood wastewater

Seafood wastewater is divided into two types:

- Seafood processing wastewater: Wastewater generated from factories and facilities using technological processes to produce seafood products such as frozen seafood, canned goods, fish sauce, etc., or from seafood trading depots.

- Aquaculture wastewater: Wastewater from ponds, lakes, etc., used for aquaculture for commercial purposes.

Generally, seafood wastewater contains the following components:

- A large amount of easily biodegradable organic matter (BOD5, COD);

- Nutrients (N, P);

- Suspended solids (TSS);

- Pathogenic microorganisms;

- In addition, wastewater from seafood processing activities also contains a specific component, chlorine.

The importance of treating seafood wastewater

Due to the harmful components mentioned above, collecting and treating seafood wastewater before discharging it into the environment is essential:

- High levels of N and P in seafood wastewater, if not properly treated, can cause eutrophication, threatening surface water environments and aquatic organisms.

- Viruses, larvae, and parasitic eggs in wastewater can cause skin and digestive diseases for humans.

- The decomposition of amino acids in seafood wastewater generates unpleasant odors, affecting the environment and the lives of surrounding residents.

- A seafood wastewater treatment system is a critical factor in environmental documentation that seafood processing plants must have to operate legally.

- Complying with legal regulations on wastewater treatment prevents administrative penalties or even business license revocation during inspections by authorities.

Current situation of seafood wastewater treatment

The issue of seafood wastewater treatment is increasingly receiving attention. Many businesses are now aware of investing in wastewater treatment systems for themselves. However, some challenges still exist:

- Many seafood processing and aquaculture facilities bypass the law due to the high cost of investing in wastewater treatment systems, which exceeds their financial capacity;

- Wastewater treatment systems are degraded and overloaded, resulting in non-compliant effluent quality;

- Outdated treatment technology no longer meets efficiency standards;

- Investors lack experience in operating the system, leading to ineffective treatment;

- Authorities are sometimes negligent in inspecting and managing wastewater collection and treatment at businesses.

Penalties for violations of wastewater treatment regulations in aquaculture

According to the Environmental Protection Law 2020 and Decree 155/2016/ND-CP, amended and supplemented by Decree 55/2021/ND-CP, violations of discharge regulations are subject to the following penalties:

- A warning is issued for discharging wastewater exceeding the technical standards for pollutants by 1.1 to 1.5 times.

- Acts of discharging wastewater exceeding technical standards by 1.1 to 1.5 times or discharging wastewater exceeding standards by less than 1.1 times in case of repeat or multiple violations are penalized as follows:

a) A fine of 300,000 to 500,000 VND for discharging less than 5 m³/day (24 hours).

b) A fine of 500,000 to 2,000,000 VND for discharging from 5 to less than 10 m³/day (24 hours).

c) A fine of 2,000,000 to 5,000,000 VND for discharging from 10 to less than 20 m³/day (24 hours).

WeMe’s MBR Technology Solution for Seafood Wastewater Treatment

Explanation

- Wastewater, after separating trash and grease, is collected in a sump. A submersible pump in the sump pumps the wastewater to the equalization tank to begin the treatment process.

- Equalization tank: Balances the flow and concentration of wastewater. Air is supplied to mix the wastewater, preventing anaerobic decomposition that causes foul odors. Wastewater from the equalization tank is pumped to the anaerobic treatment tank.

- Anaerobic tank: Dissolved organic matter and colloids are decomposed by anaerobic microorganisms, reducing BOD and COD in the wastewater. During growth, anaerobic microorganisms break down organic matter into gases such as CO2, H2S, and CH4.

- Aerobic tank: Oxygen is supplied by alternating air blowers, ensuring even air distribution for aerobic treatment. These microorganisms break down organic matter into CO2 and H2O, reducing pollutant concentrations in the wastewater.

- MBR Module: Provides the necessary amount of microorganisms to remove BOD, COD, N, P, etc. The wastewater is then pumped through the MBR membrane filter. Microorganisms, pollutants, and sludge are entirely retained on the membrane surface. Only clean water passes through the membrane. A portion of the sludge is returned to the aeration tank, while the rest undergoes mineralization in the tank and is periodically removed.

- After undergoing WeMe’s seafood wastewater treatment process, the water meets QCVN 40:2011/BTNMT Column B standards for discharge into receiving sources without the need for settling, filtration, or disinfection.

Highlights of WeMe’s Seafood Wastewater Treatment System

The standout feature of WeMe’s seafood wastewater treatment technology is the MBR module. The MBR module uses activated sludge combined with MBR membrane filtration technology. The module consists of flat sheet membranes with a pore size of 0.1 – 0.4 µm, submerged in the aerobic treatment tank. This technology has been applied by WeMe for many types of wastewater and has achieved high treatment efficiency, including in domestic wastewater, livestock wastewater, and medical wastewater.

WeMe’s seafood wastewater treatment process has the following notable advantages:

- The MBR module replaces the functions of settling, filtration, and disinfection tanks, saving area and cost as these tanks are unnecessary.

- The treated water has high transparency, guaranteed to meet QCVN standards.

- Automatic operation, no labor required. Even inexperienced investors can operate the system.

- The system is installed above ground, making maintenance easy and allowing for dismantling and relocation if needed.

- The biological treatment process does not use chemicals, making it safe, environmentally friendly, and cost-effective for chemical purchases.

- The treatment tanks and modules are pre-manufactured, allowing for quick installation in just a few days, minimizing disruption to business activities.

WeMe’s Seafood Wastewater Treatment System Quotation

WeMe’s seafood wastewater treatment technology is designed as a system with various capacities to meet customers’ treatment needs. It should be noted that the higher the treatment capacity, the lower the investment cost per cubic meter of wastewater. When partnering with WeMe, customers will receive thorough and detailed consultation and quotations. Each item is carefully calculated before being communicated to the customer to ensure honesty, objectivity, and the best market price. The seafood wastewater treatment system quotation includes the following detailed items:

- Integrated wastewater treatment module;

- Wastewater storage tank;

- Costs for equipment such as pumps, air blowers, air distribution systems, pipes, electrical wires, etc.;

- Transportation and installation costs;

- Costs for input and output sample analysis;

- Training costs for operation;

- Warranty and maintenance costs;

- Etc.

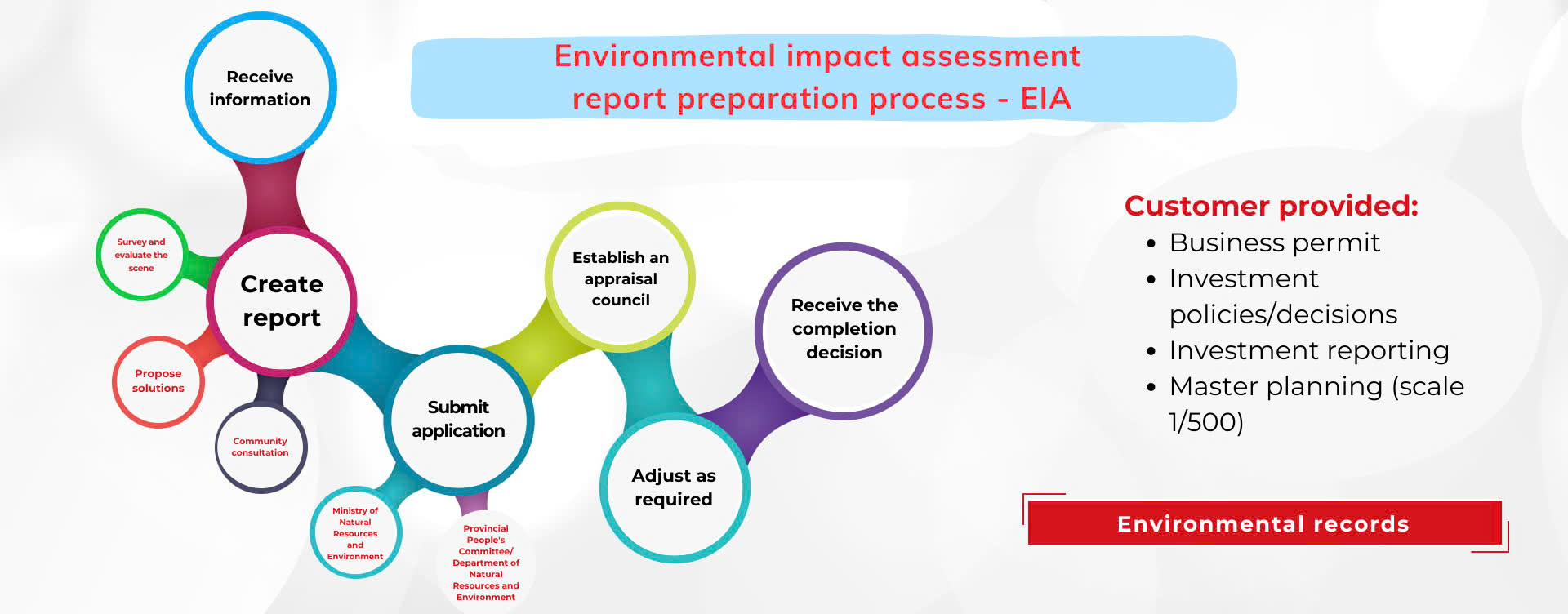

WeMe’s Project Implementation Process

The project implementation process for installing a seafood wastewater treatment system with WeMe includes simple and professional steps as follows:

- Information collection, survey, and consultation: Collect relevant information about business operations, source water characteristics, output water quality requirements, customer difficulties, and customer requirements to develop a consultation and design plan.

- Quotation and contract signing.

- System design: Detailed design of the required project components.

- Construction and installation: Transporting machines and equipment to the site and proceeding with installation.

- System trial operation.

- Installation acceptance.

- System operation and sample analysis.

- Acceptance for use and operation training.

Introduction to some similar wastewater treatment projects by WeMe

Installation of wastewater treatment modules for My Hanh Private Enterprise in Ganh Hao

- Capacity: 10 m³/day

- Investor: My Hanh Private Enterprise, Ganh Hao

- Project location: Ganh Hao town, Dong Hai district, Bac Lieu province

- Required output water quality: QCVN 14:2008/BTNMT, Column B

Project to install a wastewater treatment system for HoaLongFeed Co., Ltd.

- Capacity: 15 m³/day

- Investor: HoaLongFeed Co., Ltd.

- Project location: No. 45 De Truong Long Street, Rach Bong Hamlet, Tan Lan Commune, Can Duoc, Long An

- Required output water quality: QCVN 40:2011/BTNMT Column A

Which can WeMe’s seafood wastewater treatment system be applied to?

Currently, aquaculture is growing more and more, and some key sectors are being prioritized for development. WeMe’s seafood wastewater treatment system is designed with various capacities and can be applied to treat wastewater from:

- Shrimp farming wastewater

- Fish farming wastewater

WeMe is committed to the quality of our products and services, as well as our after-sales policy. If you are interested in WeMe’s seafood wastewater treatment system, please contact us for the most detailed consultation and support. WeMe is always looking for customers nationwide. Accompanying our customers is our greatest pride at WeMe.

WeMe Energy Joint Stock Company

| Headquarters | : 124/1 Ly Thuong Kiet, Ward 7, Go Vap District, Ho Chi Minh City |

| Hotline | : 0906.653.007 |

| : wemecompany@gmail.com | |

| Fanpage | : Môi Trường WeMe |

| Northern Region (Consultant) | : 0845.653.007 |

| Central Region (Consultant) | : 0847.653.007 |

| Southern Region (Consultant) | : 0824.653.007 |